PRODUCTS & SERVICES

Our Services

- Design, Fabrication & Repair of Custom Jigs and Fixtures

- Fabrication of Aerospace Components & Assembly

- Reverse Engineering & Obsolescence Recovery Services

- Consultancy Services

- Research & Development Support Services

- Electromechanical Assembly Service & Test

- Turn-key Solutions

Industries Served

- Aerospace

- Marine

- Oil & Gas

- Bio-Medical

Products & Services

Material Type | Material Grade |

Stainless Steel | 15-5PH H1025/H1075, 17-4 H1025, 17-4 H1075, 17-4 PH H 1150, 17-4PH H 900, 17-4PH H925, 17-4PH-A, 440C, 416 SS, SS 316, SS303, SUS 304, NITRONIC 60, NITRONIC 50, 13-8PH H1000 |

Copper Alloy | C11000, C17200, C63000, TOUGHMET 3 TS 160U, TOUGHMET 3 AT110 |

Steel | 18CrNiMo7-6, 2510, 4140, 4340, 8620, S50C,S45C, 4142M, 4130, 13CRL80 |

Aluminum Alloy | ALU 6061, ALU 6082-T6511, ALU 2024-T351, ALU 7075, ALU 5052 |

Nickel Chromium | INCONEL 718 |

Nickel Alloy | MP35 N |

Plastic | NYLON 66 GF 30%, PEEK, Delrin, PVC, Teflon |

Titanium | TITANIUM GRADE 5 / GRADE 2 |

Brass | C36000 |

Material Type & Material Grade |

Stainless Steel 15-5PH H1025/H1075, 17-4 H1025, 17-4 H1075, 17-4 PH H 1150, 17-4PH H 900, 17-4PH H925, 17-4PH-A, 440C, 416 SS, SS 316, SS303, SUS 304, NITRONIC 60, NITRONIC 50, 13-8PH H1000 |

Copper Alloy C11000, C17200, C63000, TOUGHMET 3 TS 160U, TOUGHMET 3 AT110 |

Steel 18CrNiMo7-6, 2510, 4140, 4340, 8620, S50C,S45C, 4142M, 4130, 13CRL80 |

Aluminum Alloy ALU 6061, ALU 6082-T6511, ALU 2024-T351, ALU 7075, ALU 5052 |

Nickel Chromium INCONEL 718 |

Nickel Alloy MP35 N |

Plastic NYLON 66 GF 30%, PEEK, Delrin, PVC, Teflon |

Titanium TITANIUM GRADE 5 / GRADE 2 |

Brass C36000 |

Note: All materials are non-exhaustive, please contact us for more information.

Our main area of expertise is in the design and fabrication of aerospace jigs and fixtures. We can also make improvements to existing fixtures or create new fixtures for improved performance.

We manufacture components for the Oil & Gas industry as well as consumable parts for aerospace MRO activities. Our in-house CMM capability serves as an assurance that we can meet our customers’ high standards.

We also have the ability to repair aerospace components such as turbine vanes, blades and aviation hydraulic systems design and customization of machineries of aerospace industry.

We can also provide turnkey services for manufacturing setups comprising CNC programming, providing all the necessary tooling as well as commissioning and training.

Our main area of expertise is in the design and fabrication of aerospace jigs and fixtures. We can also make improvements to existing fixtures or create new fixtures for improved performance.

We manufacture components for the Oil & Gas industry as well as consumable parts for aerospace MRO activities. Our in-house CMM capability serves as an assurance that we can meet our customers’ high standards.

We also have the ability to repair aerospace components such as turbine vanes, blades and aviation hydraulic systems design and customization of machineries of aerospace industry.

We can also provide turnkey services for manufacturing setups comprising CNC programming, providing all the necessary tooling as well as commissioning and training.

Machinery List

No | Type of Machine | Model | Maximum Workpiece Size (mm) | Unit(s) |

1 | 3 Axis Vertical Machine Centre | Matsuura R-PLUS 550 | 400 (W) x 500 (L) x 400 (H) | 5 |

2 | 4 Axis Vertical Machine Centre | Matsuura V.Plus-550 | 400 (W) x 500 (L) x 400 (H) | 1 |

3 | 4 Axis Vertical Machine Centre | Matsuura MC 550VX | 400 (W) x 500 (L) x 400 (H) | 2 |

4 | 5 Axis Vertical Machine Centre | Matsuura V-PLUS 550 | 400 (W) x 500 (L) x 400 (H) | 1 |

5 | CNC Horizontal Lathe | Mazak QT 350 | ⌀100 x 1538 (L) | 1 |

6 | CNC Lathe Machine | Okuma LB3000 EX IIIC500-e | ⌀400 x 500 | 2 |

7 | CNC Horizontal Lathe | Hwacheon Hi-Tech 200B | ⌀65 x 350 (L) | 1 |

8 | Manual Vertical Milling Machine | Shizuoka VHR-A | 300 (W) x 750 (L) x 400 (H) | 1 |

9 | Manual Horizontal Lathe | Colchester Mastiff 1400 | ⌀85 x 1400 (L) | 1 |

10 | Manual Horizontal Lathe | LeBlond Makino | ⌀300 x 65 (L) | 1 |

11 | Form Grinding Machine | Okamoto ACC 350 | 150 (W) x 350 (L) x 180 (H) | 1 |

12 | Form Grinding Machine | Okamoto ACC 350 | 150 (W) x 350 (L) x 180 (H) | 1 |

13 | Form Grinding Machine | Okamoto ACC 450CV | 150 (W) x 450 (L) x 300 (H) | 1 |

14 | Surface Grinding Machine | Okamoto ACC 63ST | 300 (W) x 600 (L) x 280 (H) | 1 |

15 | Cylindrical Grinding Machine | Okamoto OGM | ⌀150 x 450 (L) | 1 |

No | Type of Machine | Unit(s) |

1 | 3 Axis Vertical Machine Centre Model: Matsuura R-PLUS 550 Maximum Workpiece Size (mm): 400 (W) x 500 (L) x 400 (H) | 5 |

2 | 4 Axis Vertical Machine Centre Model: Matsuura V.Plus-550 Maximum Workpiece Size (mm): 400 (W) x 500 (L) x 400 (H) | 1 |

3 | 4 Axis Vertical Machine Centre Model: Matsuura MC 550VX Maximum Workpiece Size (mm): 400 (W) x 500 (L) x 400 (H) | 2 |

4 | 5 Axis Vertical Machine Centre Model: Matsuura V-PLUS 550 Maximum Workpiece Size (mm): 400 (W) x 500 (L) x 400 (H) | 1 |

5 | CNC Horizontal Lathe Model: Mazak QT 350 Maximum Workpiece Size (mm): ⌀100 x 1538 (L) ⌀420 x 1538 (L) | 1 |

6 | CNC Lathe Machine Model: Okuma LB3000 EX IIIC500-e Maximum Workpiece Size (mm): ⌀400 x 500 | 2 |

7 | CNC Horizontal Lathe Model: Hwacheon Hi-Tech 200B Maximum Workpiece Size (mm): ⌀65 x 350 (L) ⌀300 x 150 (L) | 1 |

8 | Manual Vertical Milling Machine Model: Shizuoka VHR-A Maximum Workpiece Size (mm): 300 (W) x 750 (L) x 400 (H) | 1 |

9 | Manual Horizontal Lathe Model: Colchester Mastiff 1400 Maximum Workpiece Size (mm): ⌀85 x 1400 (L) ⌀750 x 150 (L) | 1 |

10 | Manual Horizontal Lathe Model: LeBlond Makino Maximum Workpiece Size (mm): ⌀300 x 65 (L) | 1 |

11 | Form Grinding Machine Model: Okamoto ACC 350 Maximum Workpiece Size (mm): 150 (W) x 350 (L) x 180 (H) | 1 |

12 | Form Grinding Machine Model: Okamoto ACC 350 Maximum Workpiece Size (mm): 150 (W) x 350 (L) x 180 (H) | 1 |

13 | Form Grinding Machine Model: Okamoto ACC 450CV Maximum Workpiece Size (mm): 150 (W) x 450 (L) x 300 (H) | 1 |

14 | Surface Grinding Machine Model: Okamoto ACC 63ST Maximum Workpiece Size (mm): 300 (W) x 600 (L) x 280 (H) | 1 |

15 | Cylindrical Grinding Machine Model: Okamoto OGM Maximum Workpiece Size (mm): ⌀150 x 450 (L) | 1 |

Specialised Measuring Instruments

No | Type of Instrument | Model Number | Precisions |

1 | Co-ordinate Measuring Machine | Zeiss Contura G2 | Capacity Size: 1000 x 1200 x 600 mm Max. table load: 500kg Accuracy: 0.0001mm |

2 | Smart Scope | OGP Flash 200 | Capacity Size: 200mm x 200mm Max. table load: 15kg Accuracy: 0.001mm |

3 | Height Master Gauge | Mitutoyo 515-301 | Capacity Size: 600mm Accuracy: 0.001mm |

No | Type of Instrument | Unit(s) |

1 | Co-ordinate Measuring Machine Model: Zeiss Contura G2 Precisions: Capacity Size: 1000 x 1200 x 600 mm Max. table load: 500kg Accuracy: 0.0001mm | 1 |

2 | Smart Scope Model: OGP Flash 200 Precisions: Capacity Size: 200mm x 200mm Max. table load: 15kg Accuracy: 0.001mm | 1 |

3 | Height Master Gauge Model: Mitutoyo 515-301 Precisions: Capacity Size: 600mm Accuracy: 0.001mm | 2 |

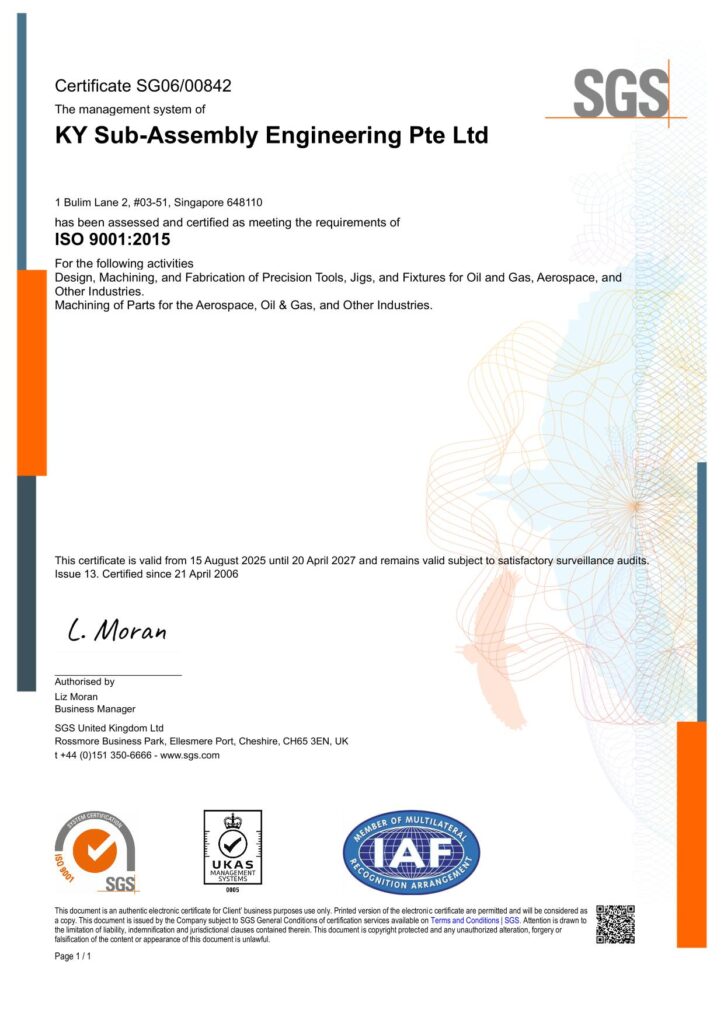

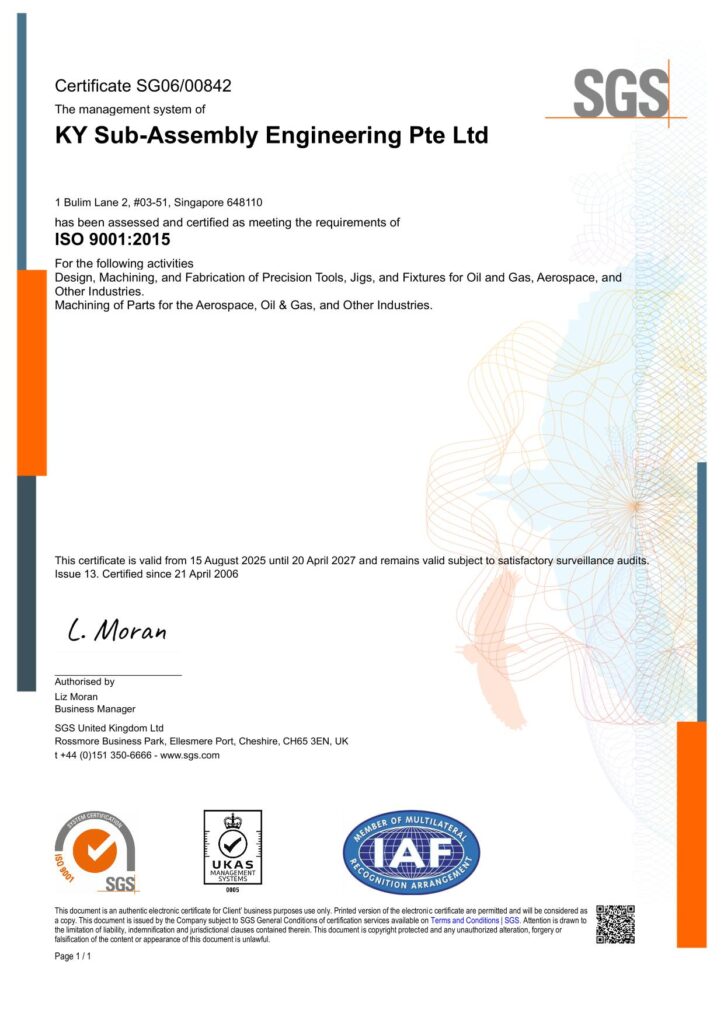

Quality

As an ISO 9001 certified company, we exercise a comprehensive Quality Management System to ensure a high standard of quality to satisfy our customers’ needs.

Quality

As an ISO 9001 certified company, we exercise a comprehensive Quality Management System to ensure a high standard of quality to satisfy our customers’ needs.